이차전지 양극 활물질(NCM) 소성

설비제작

KEY POINT

- 성로 내부 온도 정밀도 ( +/- 5 °C ) 형성을 위한 설계

- 소성로 내부 산소 분압을 위한 밀봉 설계 제작

- 기존 소성로 (RHK) 대비 생산량 증대 효과 ( 동일 조건 약 3배 )

- 소성로 유지보수 최소화를 위한 소요부품 선정 필수

이차전지 양극 활물질(NCM) 소성 가열로 설비

종류 및 장단점

-

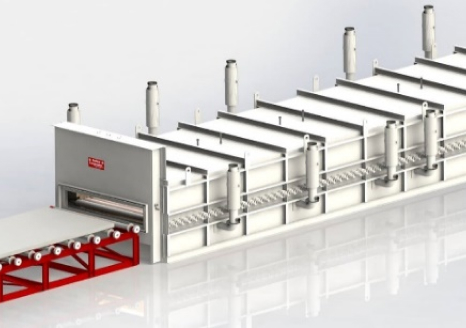

ROLLER HEARTH KILN

장점

- 원료 소성 중 손실되는 비열 값을 최소화하여 최적의 온도 조건을 형성 시킬 수 있다

단점

- SIC ROLLER 의 고온 하중 및 열 충격으로 인한 손상 때문에 MULTI- LAYER BY LAYER ( 다열, 다단 ) 적재가 불가하므로 생산량이 적고, ROLLER의 파손으로 인한 유지보수 비용이 높다는 것이 단점이다.

-

PUSHER PLATE TUNNEL KILN

장점

- 내부 온도 분포도가 뛰어나고 로내 분위기 조건 형성이 가능함

- ALUMINA HEARTH TILE 및 PLATE의 비열 값으로 인해 ROLLER HEARTH KILN에 보다 더 많은 발열량이 필요함

단점

- PUSHER PLATE JAM 현상 발생

- 하부 구조의 안정성 때문에 다단 설치가 가능하나 3열 이상의 TRAY LAYER 설치가 불가함

-

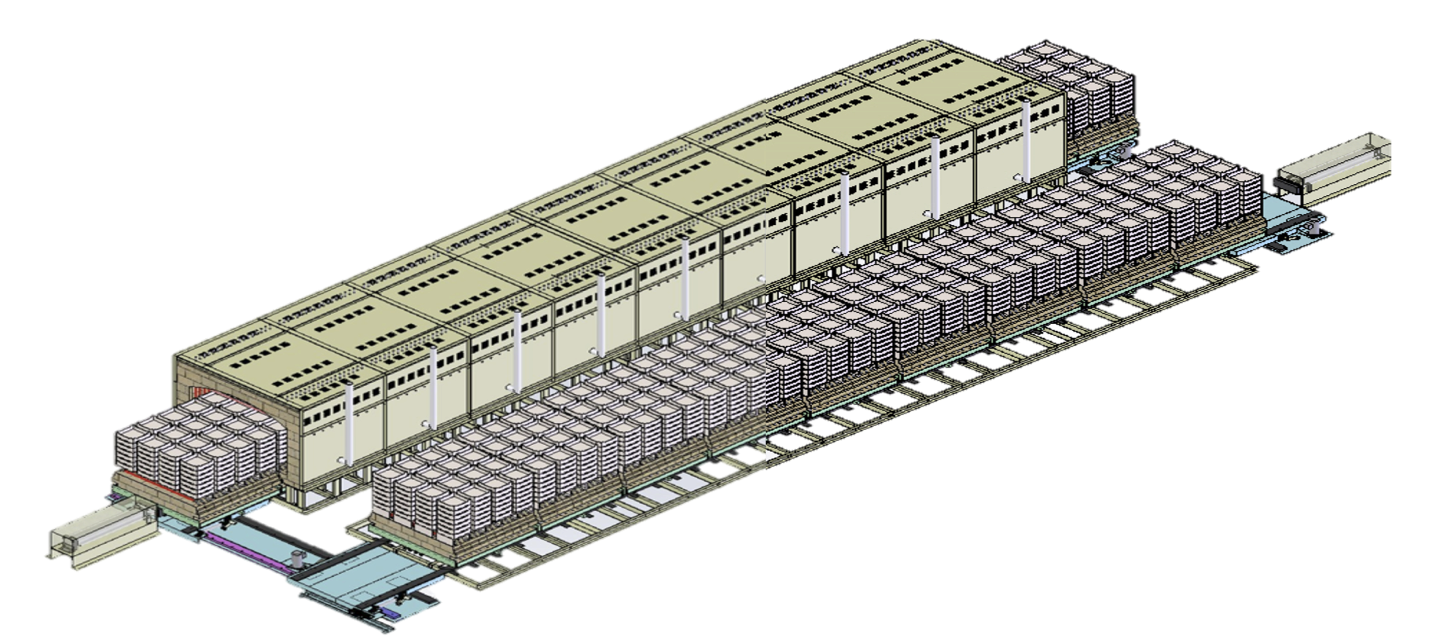

CAR TUNNEL KILN

장점

- 다단 및 다열 적재가 가능해서 대량 생산이 가능하다.

- ROLLER 나 PLATE ( 대판) 적재가 없으므로 유지 보수가 용이하다

단점

- 온도 조건에 필요한 상하 대칭 가열 형성이 불가하여, 가열로 내부 상하 온도 편차가 심하다는 단점이 있음

대안

- 하부 가열 및 HEAT BALANCE를 형성해서 조건 구성

자사 CAR TUNNEL의 장점

- 소성로 내부 가열부 온도 조건을 +/- 5 °C 이내로 제어가능

- 기존 RHK 대비 동일규격에서 생산량 ( 소성 처리량 ) 최대 3.5배 이상 가능

- 산소 분압 조건에 적용 할 수 있는 밀봉 조건 형성 및 입출구에 분위기 CHAMBER 별도 구성

- 발열체 수명 연장 ( 최소 2년에서 최대 4년 사용 가능 )

- RHK의 문제점인 SIC ROLLER 파손 및 발열체 손상으로 인한 유지보수 비용 절감 그리고 소성로 연속 생산 체계 확보 가능

CAR TUNNEL KILN

| 용도 | 이차전지 양극 활 물질 소성 |

|---|---|

| 최대 온도 | 1,050 °C |

| 사용 온도 | 780 – 950 °C |

| 생산 량 (INPUT) |

22,292 kg/day - 669 ton/month – 8,000 ton/year ( one cycle time : 24시간 기준) |

| 생산 (작업) 조건 | 24hrs/day - 30 days/month |

| 대차 수량 | KILN내부 : 36식 / RETURN TRACK : 37식 |

| 대차 1식당 BOAT 적재량 | 112 Boats/One Kiln Car |

| 대차 1식당 원료 적재량 | 616 kg / One Kiln Car ( 대차 36식 – 총 22.3ton) |

| KILN 내부 규격 | 1,950 W x 1,150 H x 55,440 L (mm) |

| KILN 외부 규격 |

6,250 W x 2,750 H x 62,000 L (mm) (RETURN TRACK + 대차 이송장치 포함) |